GARRECO PRINT

Getting Started Guide

This Getting Started Guide provides helpful information to get the best experience from our resins and includes handling of the materials, safety, post-processing, and general information. Check out our Frequently Asked Questions for additional support or contact us if you have questions.

General Information

Resin Handling

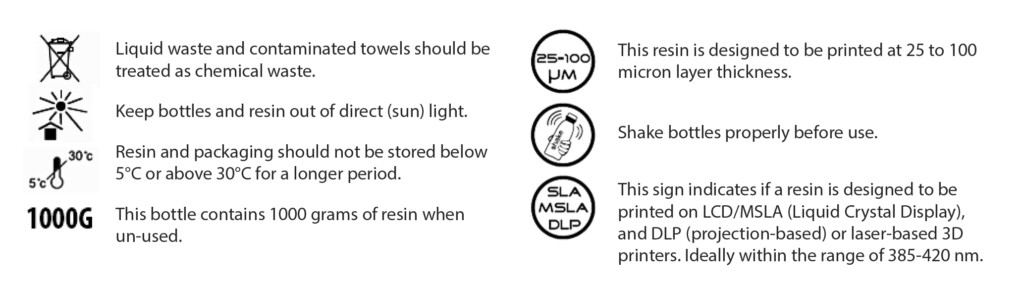

Shake the bottle for at least 1 minute before use. After shaking leave the resin to rest for 10 minutes to let air bubbles escape. The resin can be poured back into the bottle after use. Check the resin for residual pieces of polymer before pouring back the resin in the bottle.

Always use protective measures when handling Garreco Print resins. Extended safety instructions can be found in the product Safety Data Sheets.

Compatible 3D Printers

Most of our resins are either LCD and DLP or SLA and DLP. The resins in the LCD category have a higher reactivity to generate a higher print speed on low-power 3D printers. A wide range of 3D printers have been validated with Garreco Print resin, which includes the Shining3D, UnionTech, Asiga, Anycubic Photon, Kudo3D Bean, Phrozen, and many more. A complete list of compatible printers plus the latest settings is available here.

Support Settings

Post-Processing

Post-processing includes rinsing a maximum of 6 minutes in 99% Pure Isopropyl Alcohol (we recommend Clean 99), resin cleaner, or (Bio) Ethanol, preferably ultrasonic or under agitation. Make sure the parts are dry before post-curing, by placing the parts in a well-ventilated area for at least 30 minutes or use pressurized air for 2 minutes for 99% Pure Isopropyl Alcohol and (bio) Ethanol. The last step includes curing in a high-power UV curing chamber. The latest post-curing instructions are available here.

Caution: Uncured printed objects could break or crack if exposed to solvents, 99% Pure Isopropyl Alcohol, resin cleaner, or (Bio) Ethanol for longer than 20 minutes.

Caution: Uncured printed objects need to be completely dry before post-curing. Curing wet and or sticky parts can lead to parts with surface defects.

Caution: Using a low-power curing unit can lead to inferior part properties.

Caution: Always use protective measures when handling Garreco Print resins or uncured printed objects. Parts are safe to touch without gloves after proper post-processing.

Safety

Garreco Print resins and uncured printed objects should always be handled with care using the advised precautions such as gloves, glasses, and protective clothing. Discard all disposables that have been in contact with resin as chemical waste. Check the product Safety Data Sheet for more information.

6.1 Spill Cleaning Protocol

Spilled resin can be cleaned with standard rinsing solvents like 99% Pure Isopropyl Alcohol such as Clean 99 or (bio) Ethanol. Treat paper towels with resin as chemical waste.

Storage & Transport

Garreco Print resins should be stored in the original package in a dark and dry area between 41°F and 86°F (5°C and 30°C). Close the packaging after every use. For transport, the resins should not be exposed to temperatures above 140°F (60°C) to ensure usability within the expiry date.

Plastic & Packaging Waste

Fully polymerized Garreco Print resins can be treated as plastic waste and are not harmful to the environment. The liquid residue (washing solvent and contaminated papers included) should be treated as chemical waste and disposed of as such. Cardboard packaging can be recycled.

Need Additional Support?

Still have questions about Garreco Print 3D resins? Please Contact Us for additional support and questions.